Capabilities

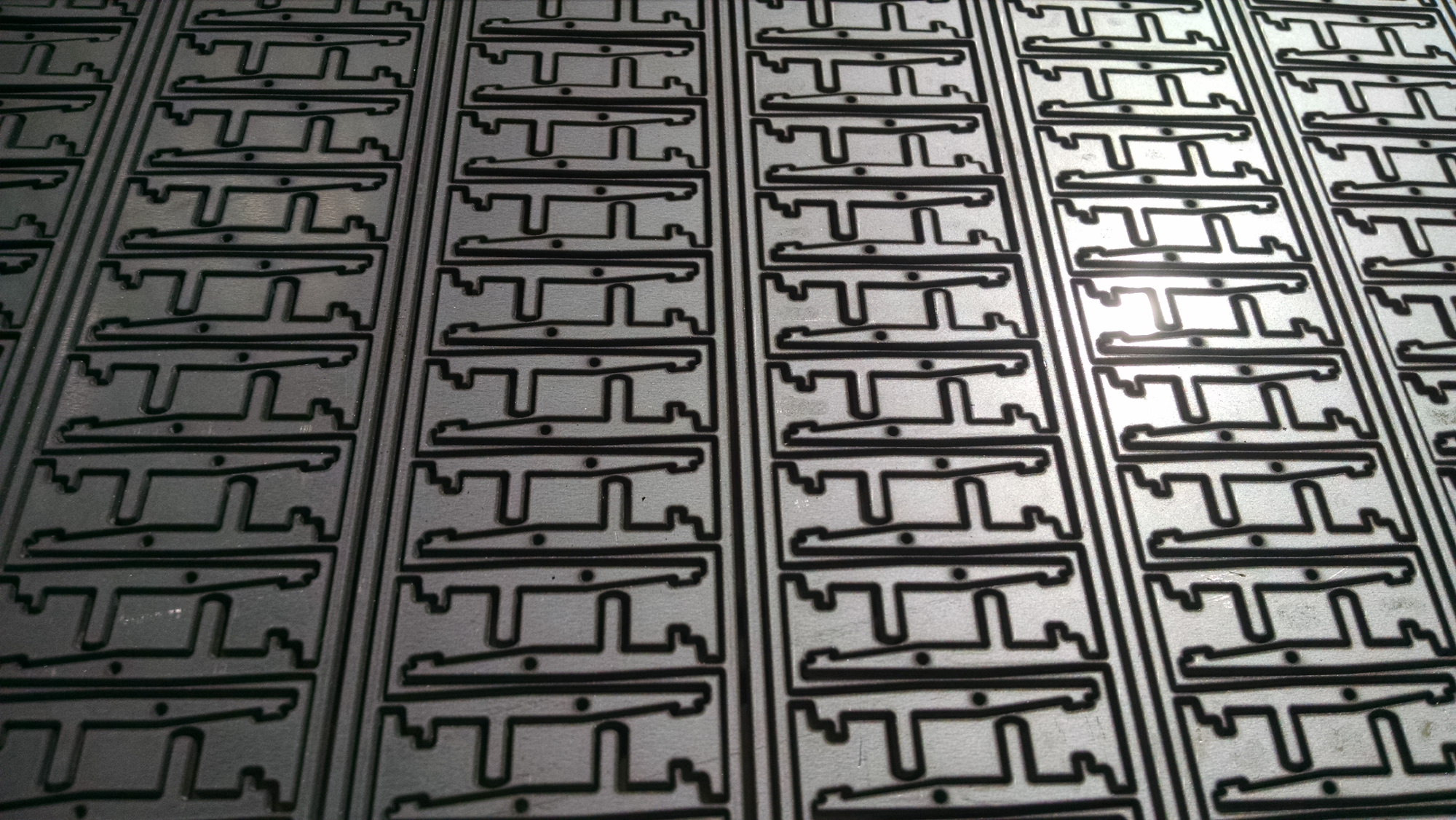

Colorado WaterJet delivers custom parts by using abrasive waterjet to cut nearly any material and thickness. Our team combines advanced equipment, tuned systems, and decades of experience to help manufacturers get parts done right and on schedule. Whether you need prototypes, short runs, or full production quantities, we deliver consistent quality without heat-related distortion or secondary finishing.

Materials We Cut

Waterjets can cut just about anything. Waterjet cutting produces clean, sand-blasted edges without heat, making it ideal for materials that melt, produce slag, or cause a Heat-Affected-Zone (HAZ) with high temperatures of other cutting methods.

We regularly cut materials including:

- Metals: aluminum, stainless steel, mild steel, titanium, copper, Inconel, tool steels

- Plastics: Delrin, UHMW, acrylic, polycarbonate, PVC, nylon, Teflon

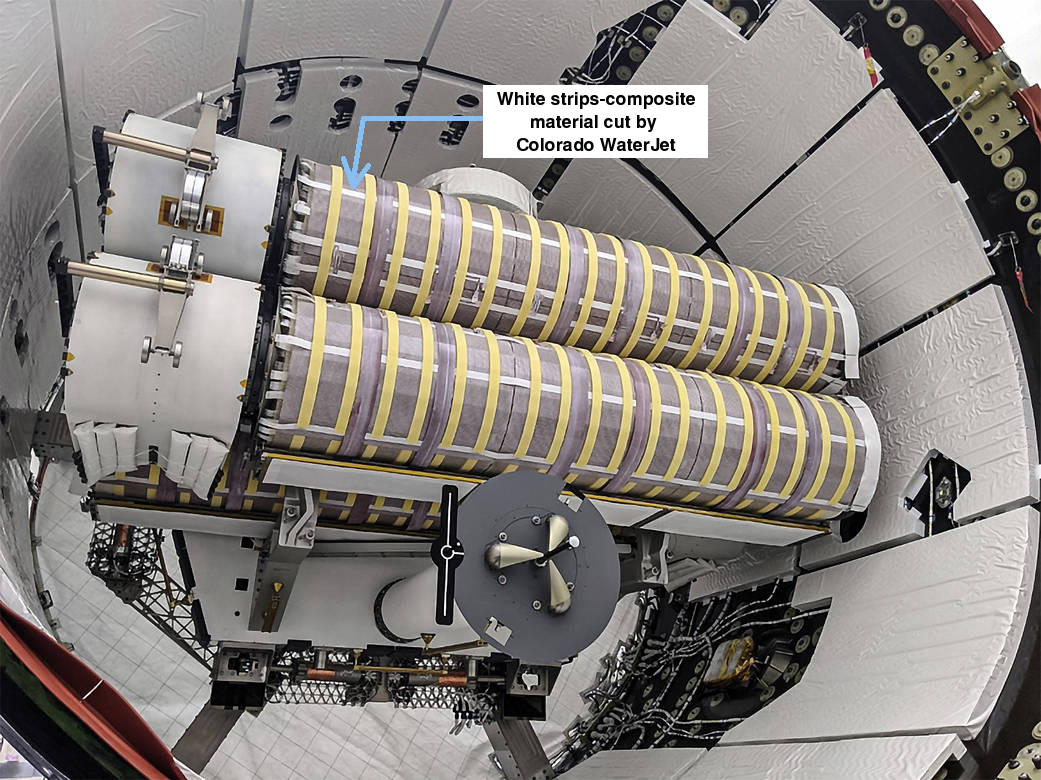

- Composites: carbon fiber, G10, fiberglass, phenolics, laminates

- Foam and rubber: gasket material, silicone, neoprene, cork

- Stone and tile: granite, marble, ceramic, porcelain

- Glass: standard (non-tempered) only

Cutting Specs

Colorado WaterJet’s equipment allows us the flexibility to meet your specifications. With a variety of table sizes, drill and 5th axis capabilities, CWJ offers options most water jet companies don’t have. We can also provide material certs, traceability reports, and inspection reports on request.

- Table sizes: 5’ x 10’, 7’ x 13’, 7.5’ x 15′

- Max material thickness: hard materials up to 8″, softer materials up to 12”

- Min material thickness: .001”

- Standard tolerance: ±0.005″

- Drill attachment for composite materials to avoid delamination

- Bevel cutting: up to 45° angle using 5th-axis waterjet head

- Standard turnaround: 2 weeks

- Expedited options: 1, 3, or 5 days

Machines

We run three large-format waterjet systems, each tuned for precision and efficiency. Whether you’re cutting oversized plates, layered sheets, or enclosures, these machines are built to deliver accurate, consistent results.

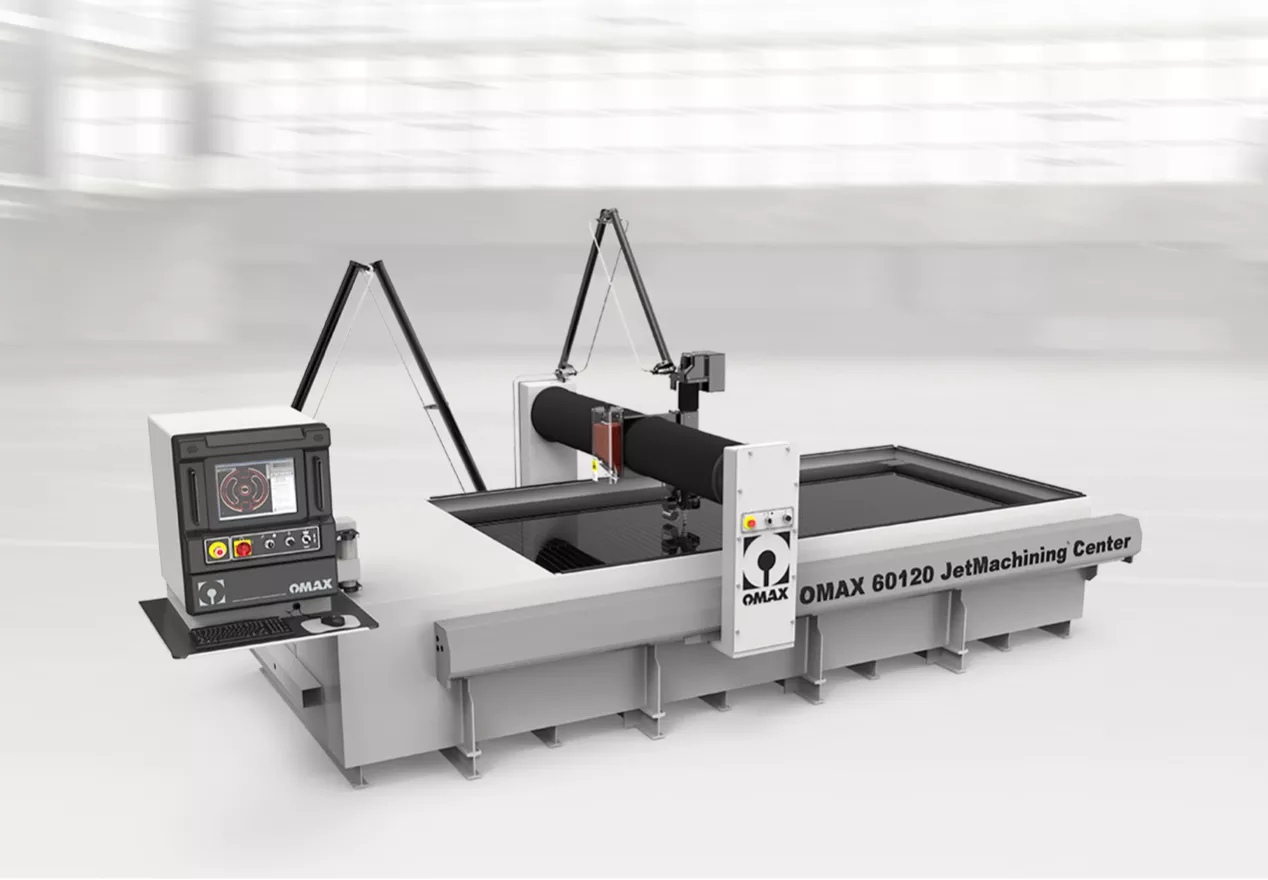

OMAX 60120 – 40 Horsepower OMAX EnduroMAX pump

This machine has a pneumatic drill attachment for pre-drilling more brittle materials. This can be particularly useful for waterjetting plastics, carbon fiber, fiberglass, acrylics, and polycarbonates. The initial velocity of a waterjet can sometimes cause de-lamination or cracking of more brittle materials. Pre-drilling with the pneumatic drill leaves a hole for the waterjet to utilize as its piercing hole, eliminating the stress to the material.

- Table size: 5’0″ x 10’0″

-

Standard Tolerance: ±0.005″

-

Positional accuracy: ±0.001″

-

Perfect for composites and to avoid delamination

OMAX 80X – 50 Horsepower OMAX EnduroMAX pump

This machine is the workhorse of waterjets, offering precision, performance and power. It is ideal for cutting larger or multiple part projects in a variety of materials. The 80X Series employs a linear drive technology designed exclusively for the abrasive waterjet environment, ensuring superior accuracy and high durability for greater productivity and profitability. It doesn’t create heat-affected zones or mechanical stresses and leaves behind a satin-smooth edge, reducing secondary operations.

- Table size: up to 7’5″ x 15’0″

- Standard Tolerance: ±0.005″

- Positional accuracy: ±0.001″

- Ideal for tight nesting and high-volume runs

- Consistent edges across large formats

Flow Mach 4c – 87,000 psi intensifier pump with 5th-axis waterjet head – Beveled cutting

The Flow Waterjet Mach 4c is an industrial-grade, 5-axis waterjet cutting system known for its advanced Dynamic Waterjet® XD technology, high speeds, and accuracy for cutting various materials. It utilizes a Nexen Roller Pinion System (RPS) for precise movement, can accommodate multiple cutting heads for increased productivity, and is designed for applications requiring high precision, such as 3D and bevel cutting.

-

Work envelope: up to 6’0″ x 13’0″

-

Standard Tolerance: ±0.005″

-

Z-axis travel: 12″

-

Positional accuracy: ±0.0005″

-

Cuts bevels, countersinks, and angled features with clean finishes

ITAR Certified and Ready for Critical Work

We are ITAR Registered, meaning your parts are produced and handled under strict U.S. security and confidentiality standards. This matters when precision, traceability, and compliance are non-negotiable.

We maintain a robust internal Quality Management System (QMS) and pass regular audits from ISO-driven customers. This process helps ensure parts arrive exactly how you expect, to print and on schedule.

We can include:

- Material certifications

- Traceability reports

- Inspection documentation

If you require documentation or compliance details, please contact us. We will provide what you need to meet your project requirements.

Prototyping and Production Runs

Whether you need a single prototype or thousands of parts, our process scales to meet your volume. We deliver repeatable results and clear communication from quote to delivery.

-

Research & Development

-

Prototypes

-

Short runs

-

Full production

Expedited Turnaround and Flexibility

Our Master Production Schedule (MPS) keeps everything moving, so nothing falls through the cracks.

-

Standard turnaround: 2 weeks

-

Expedited options: 1, 3, or 5 days based on project scope

Advanced Techniques

Colorado WaterJet offers dynamic cutting for situations where edge perpendicularity is critical. By adjusting the cutting angle, our machines can put all of the taper onto the scrap sections of the material, leaving the parts with straight edges and clean corners.

We also have extensive experience with part fixturing and secondary operation cutting. With special jobs ranging from cutting bolt holes into cast pump housings to re-profiling race car brake pads, we can help you overcome the challenges of a fast paced and demanding business world. Our 5-axis cutting capabilities can be utilized for three dimensional (3D) shapes, such as weld joints and bevels up to 45 degrees. Material flatness is critical to tight tolerance 5-Axis cutting.

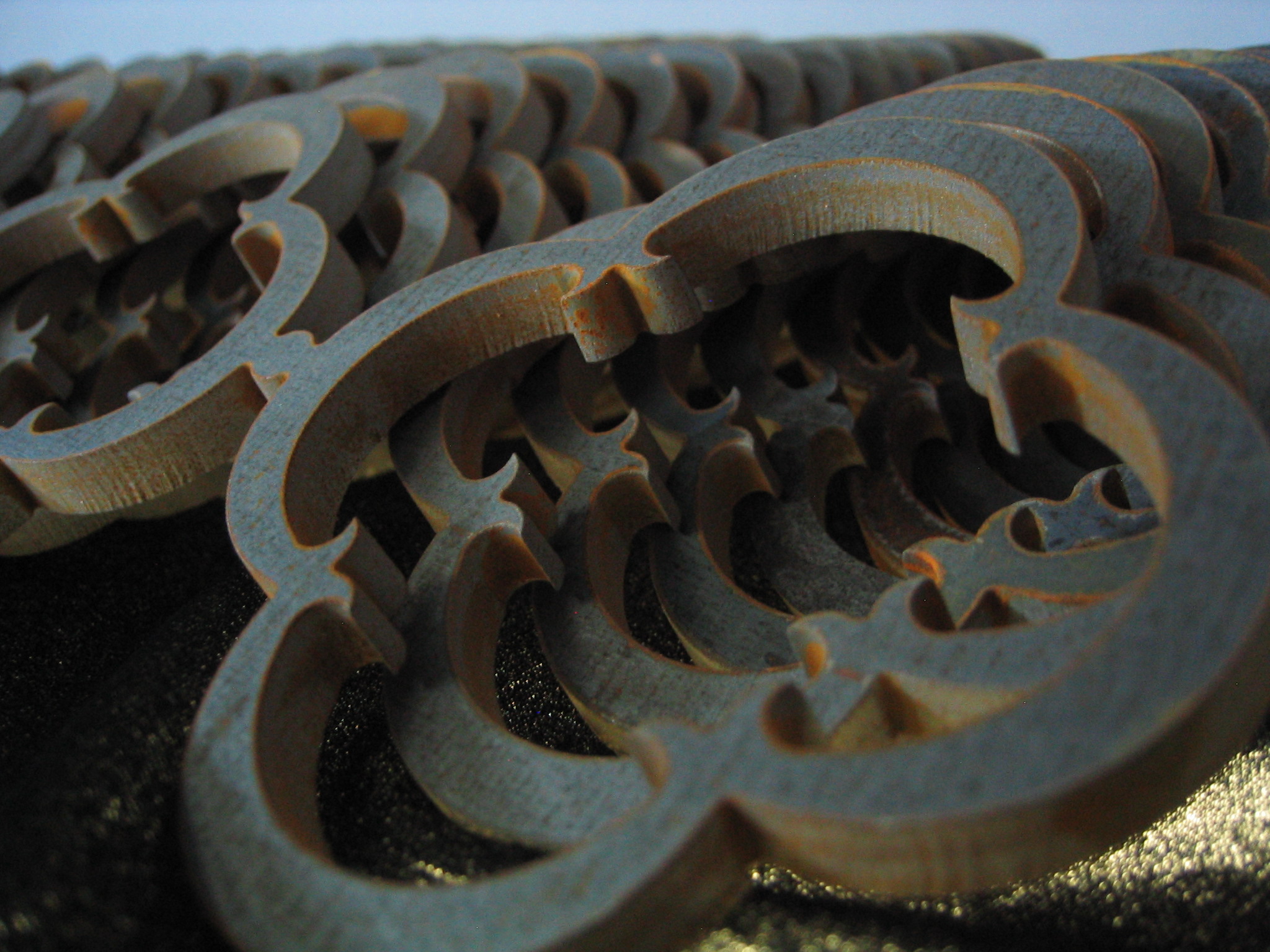

Dynamic cutting is also desirable for architectural projects and artwork that can be viewed from both sides as the cut profile will look the same regardless of whether the front or the back of the piece is viewed.

Why Choose Waterjet Cutting?

Waterjet cutting uses a high-pressure stream of water and abrasive media to create precise, clean edges on nearly any material. Unlike high temperature cutting methods, it produces no Heat-Affected Zones (HAZ), which protects material integrity and finish.

Alternative Cutting Methods

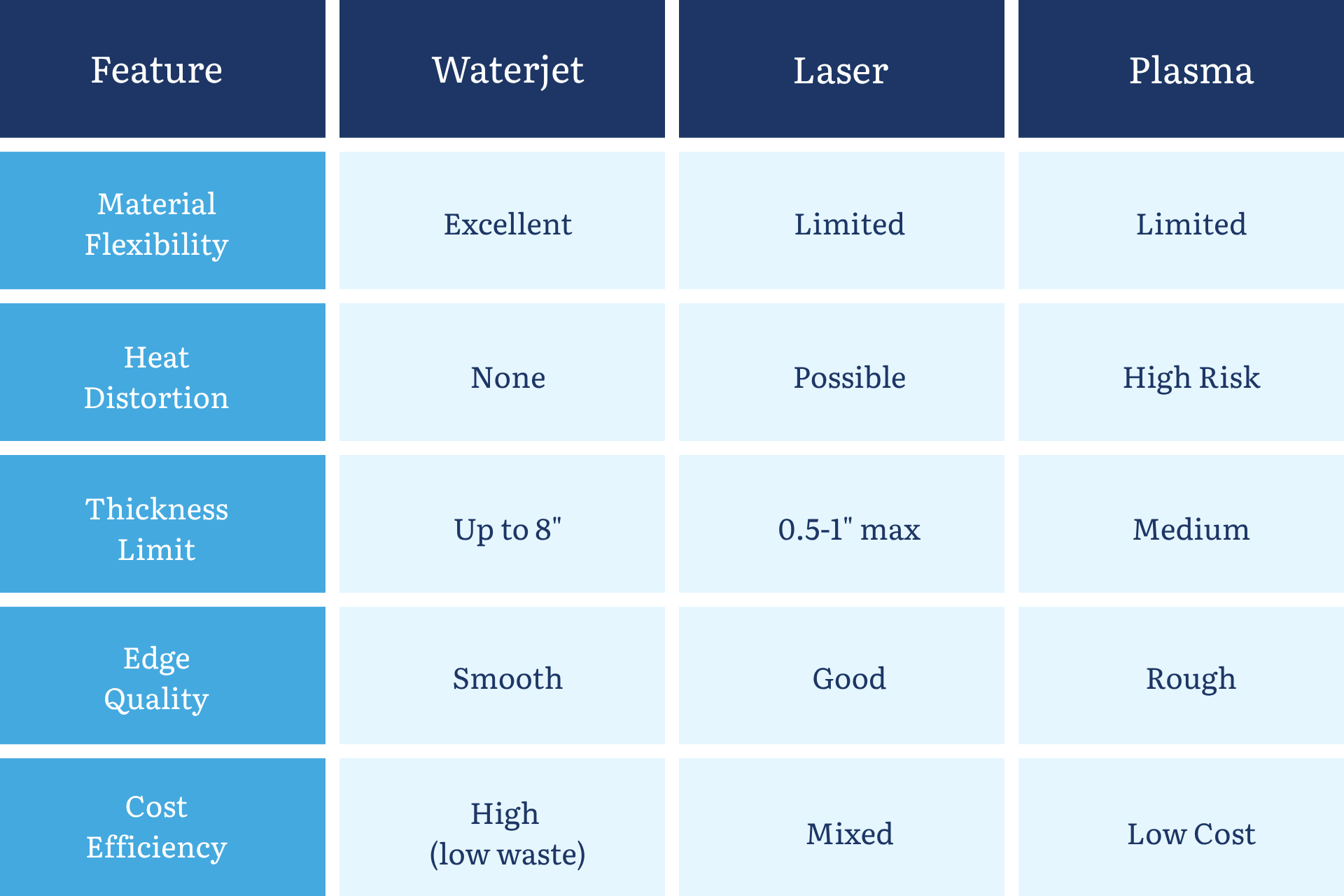

Choosing the right cutting method depends on your material, tolerance, and production needs. We partner with established laser and HD plasma shops if waterjet isn’t the right cutting method for your project.

Here are some guidelines to consider:

Frequently Asked Questions

What thickness can you cut?

Any material thickness within our cutting envelope: Min material thickness: .001” to max material thickness: hard materials up to 8″, softer materials up to 12”.

Can you cut prototypes and production parts?

Yes. We can cut single prototypes or scale up to full production quantities with the same process.

Do you provide certifications or traceability for materials?

Yes. We can include material certifications, traceability documentation, and inspection reports with your parts when needed. Our internal Quality Management System ensures every project is tracked and documented to meet your requirements.

Ready to Get Started?

Request a quote to talk through your project. We’ll respond quickly with the details you need to plan your next job.