Materials

WATERJET CUTTING FOR VIRTUALLY ANY MATERIAL AND THICKNESS

At Colorado WaterJet, we can cut near-net or final shapes from any material and any thickness within our cutting envelope. Our tuned systems and experienced team help you hit tight specs, short lead times, and shifting production demands with no heat distortion, burr, or secondary finishing required.

Waterjet cutting produces clean, sand-blasted edges without heat, making it ideal for materials that melt, produce slag, or cause a Heat-Affected-Zone (HAZ) with high temperatures of other cutting methods.

Metals

Used in aerospace enclosures, brackets, mounting plates, and heavy-duty panels where distortion-free precision matters.

-

Aluminum

-

Stainless steel

-

Mild steel

-

Titanium

-

Copper

-

Brass

-

Silicone Bronze

-

Inconel

-

Tool Steels

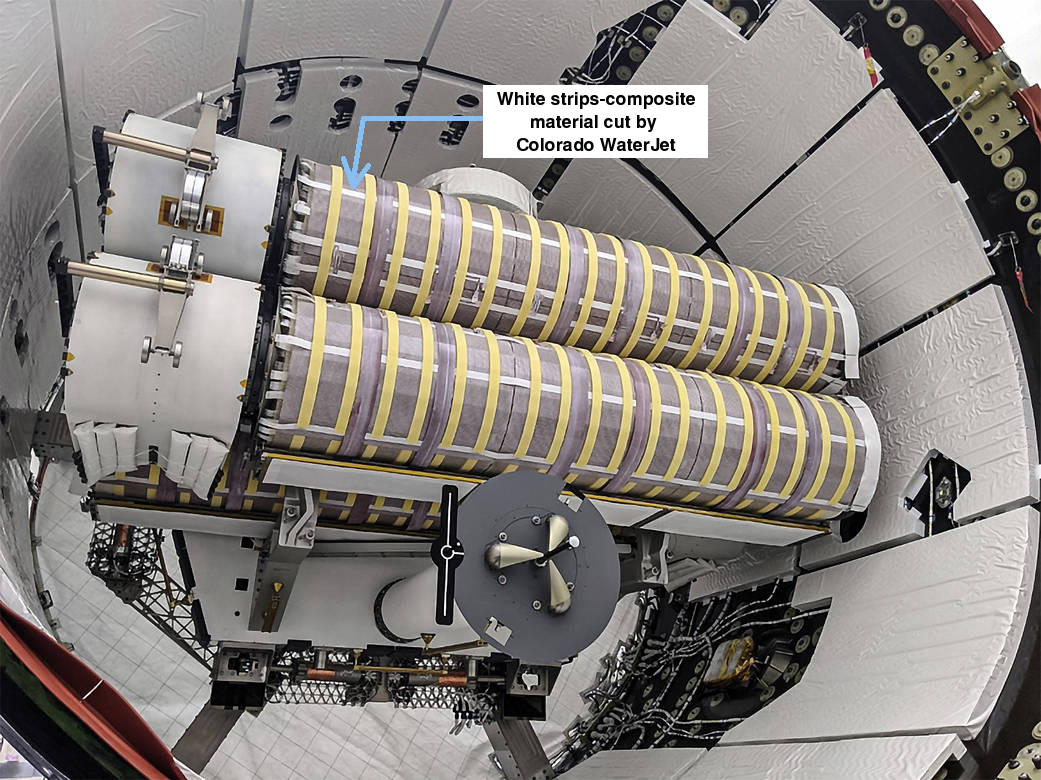

Plastics and Composites

Common in medical equipment, enclosures, test fixtures, and lightweight structural assemblies, especially where clean edges or no delamination are critical.

Plastics:

-

Delrin

-

UHMW

-

HDPE

-

Acrylic

-

Polycarbonate

-

PVC

-

Nylon

-

Teflon

Composites:

- Carbon fiber

- G10

- Fiberglass

- Phenolics

- Laminates

Rubber, Wood, Stone & More

Ideal for seals, gaskets, vibration damping, or custom packaging where edge quality and compressibility must be preserved.

Foam and Rubber:

- Gasket material

- Silicone

- Neoprene

- Cork

Stone, Tile & Glass:

-

Granite

-

Marble

-

Ceramic

-

Porcelain

- Standard Glass

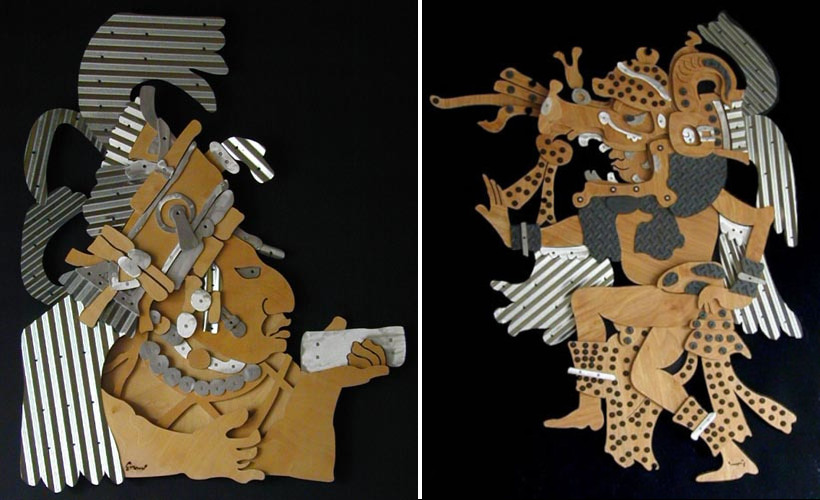

Wood:

- Hardwoods: Oak, maple, and teak

- Softwoods: Pine and cedar

- Engineered Woods: Plywood, Medium-Density Fiberboard (MDF), and laminated woods

- Other Woods: exotic woods, strand boards, and other fabricated wood materials.

Frequently Asked Questions

What thickness can you cut?

Any material thickness within our cutting envelope: Min material thickness: .001” to max material thickness: hard materials up to 8″, softer materials up to 12”.

Can I supply my own material?

Yes. Whether you supply your own material or we source it, your parts are cut with the same equipment, processes, and standards.

Do you provide material certifications or traceability?

Yes. We offer full documentation upon request, including traceability, material certs, and inspection reports.

What materials are best suited for waterjet cutting?

Waterjet performs best on metals, plastics, and composites where heat-free cutting, clean edges, or precision are essential. We can also cut soft materials like foam, rubber, and tile when clean profiles and minimal compression are required.

Can a waterjet handle layered materials?

Yes. We frequently cut multi-sheet layers, and composite assemblies with repeatable accuracy and minimal setup time.

Ready to Get Started?

Request a quote to discuss your material and design requirements. We will respond quickly with options and recommendations.