Project Capabilities

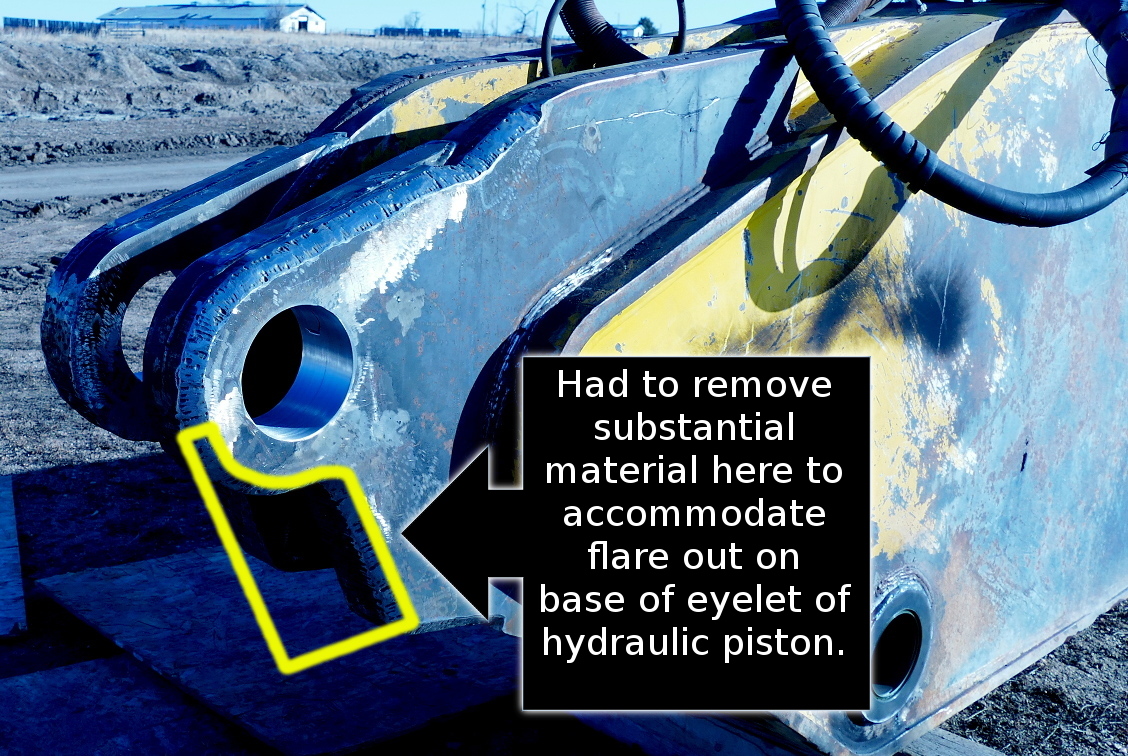

Excavator needing longer stick to dig deeper

Modified Stick – Structural Questions

Masonite prototype

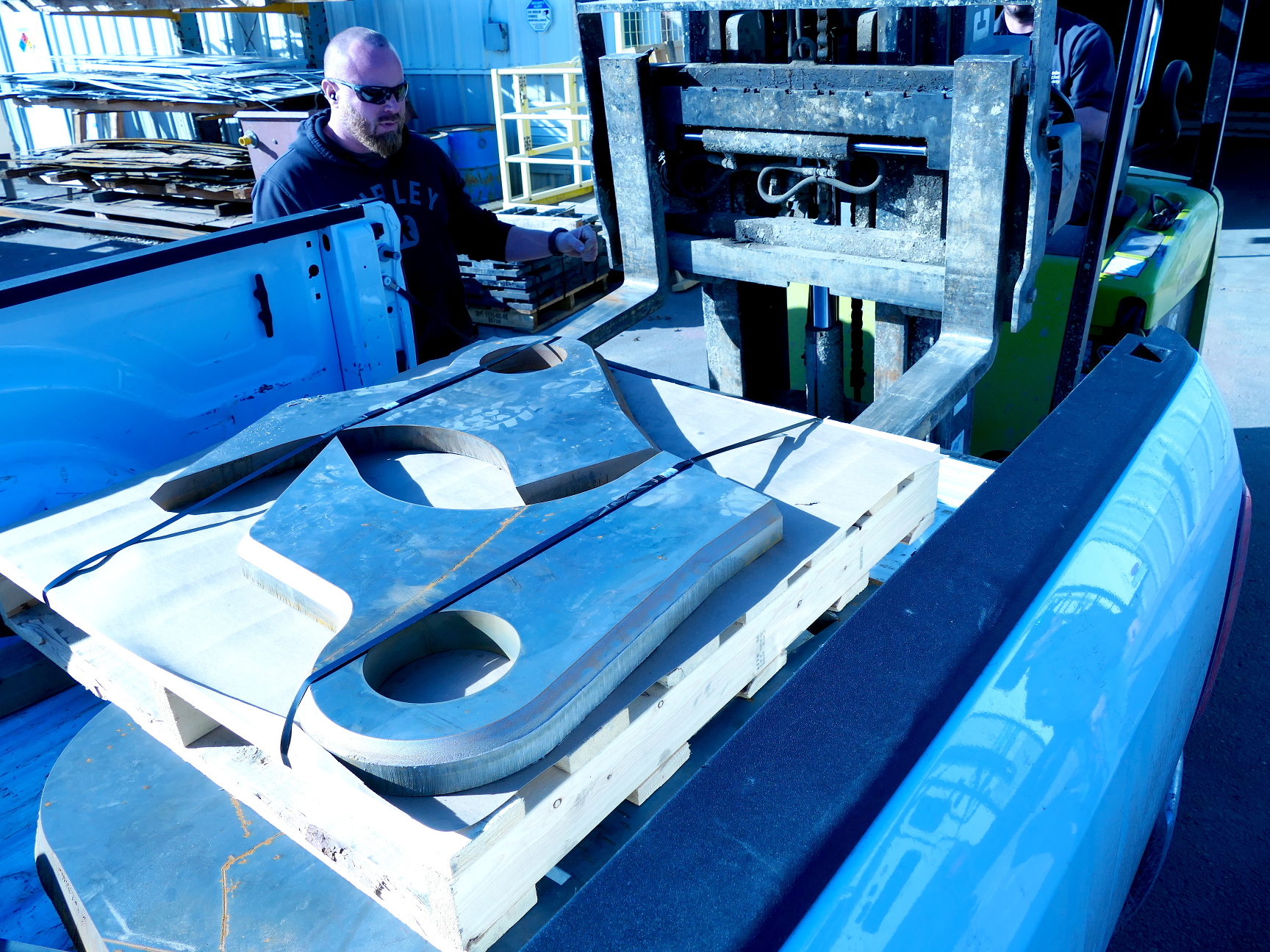

Cut a plate of 2″ steel

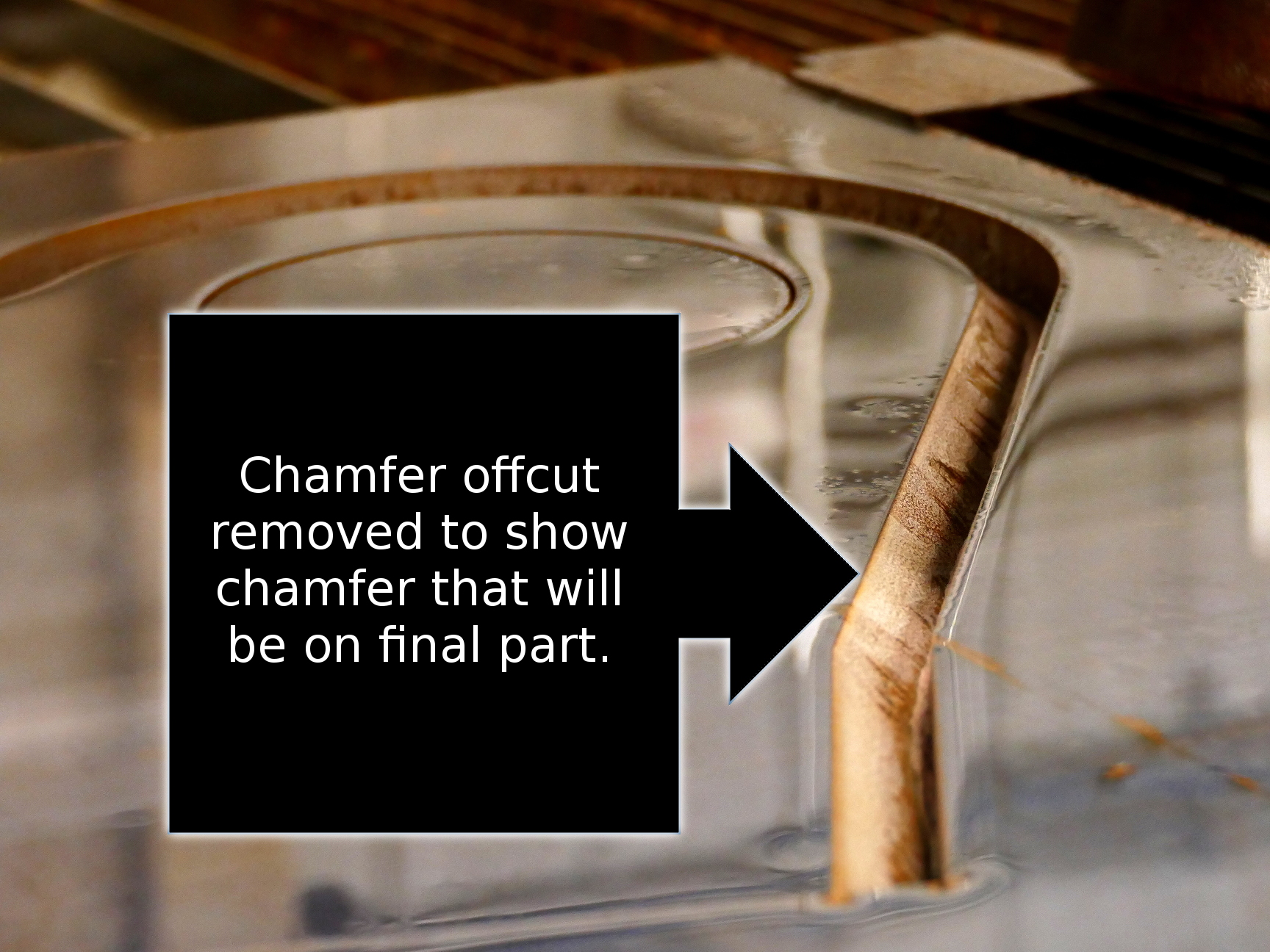

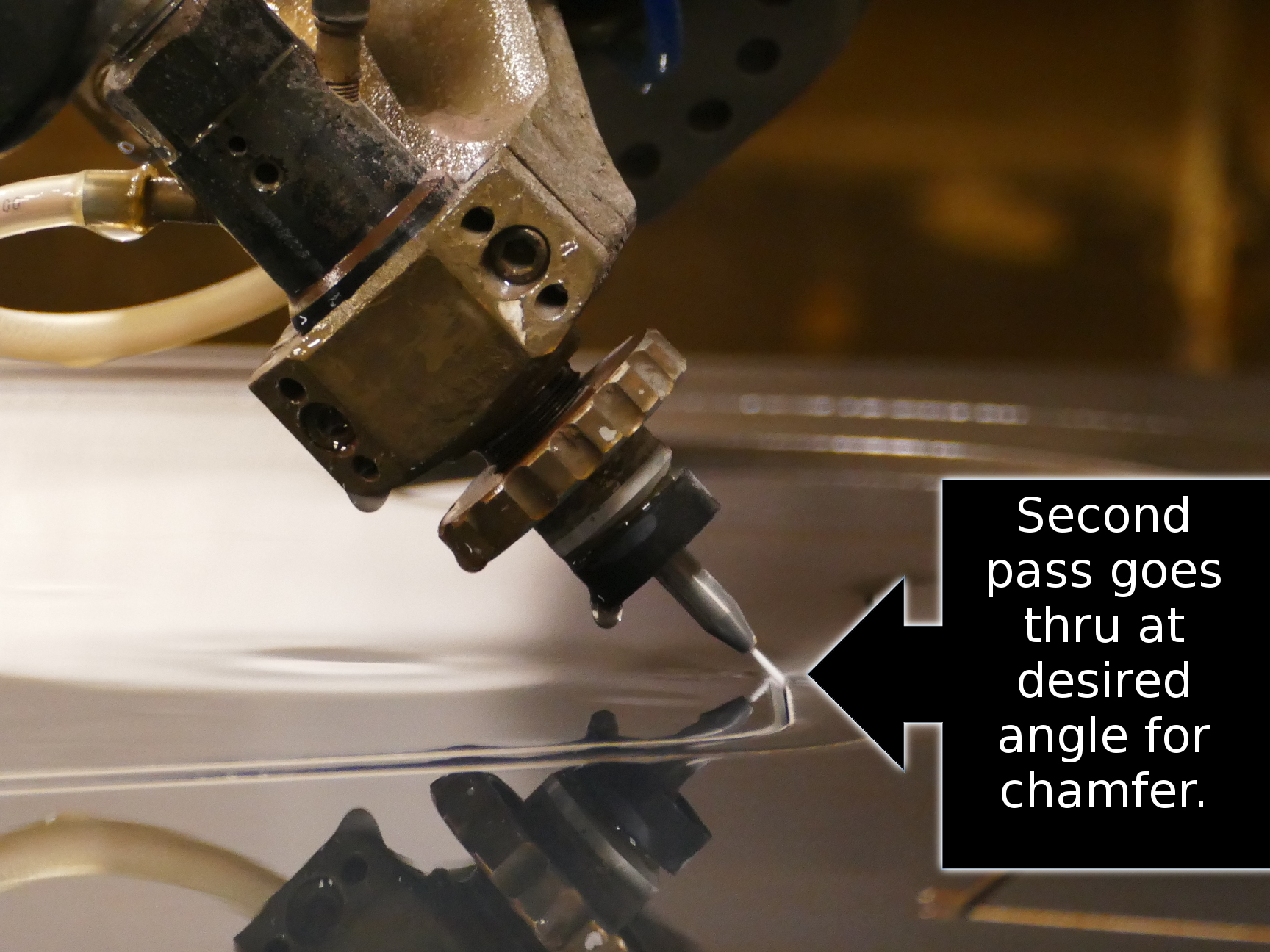

Chamfer as weld prep in a 2″ piece of steel.

Removing part from waterjet table using magnet and forklift.

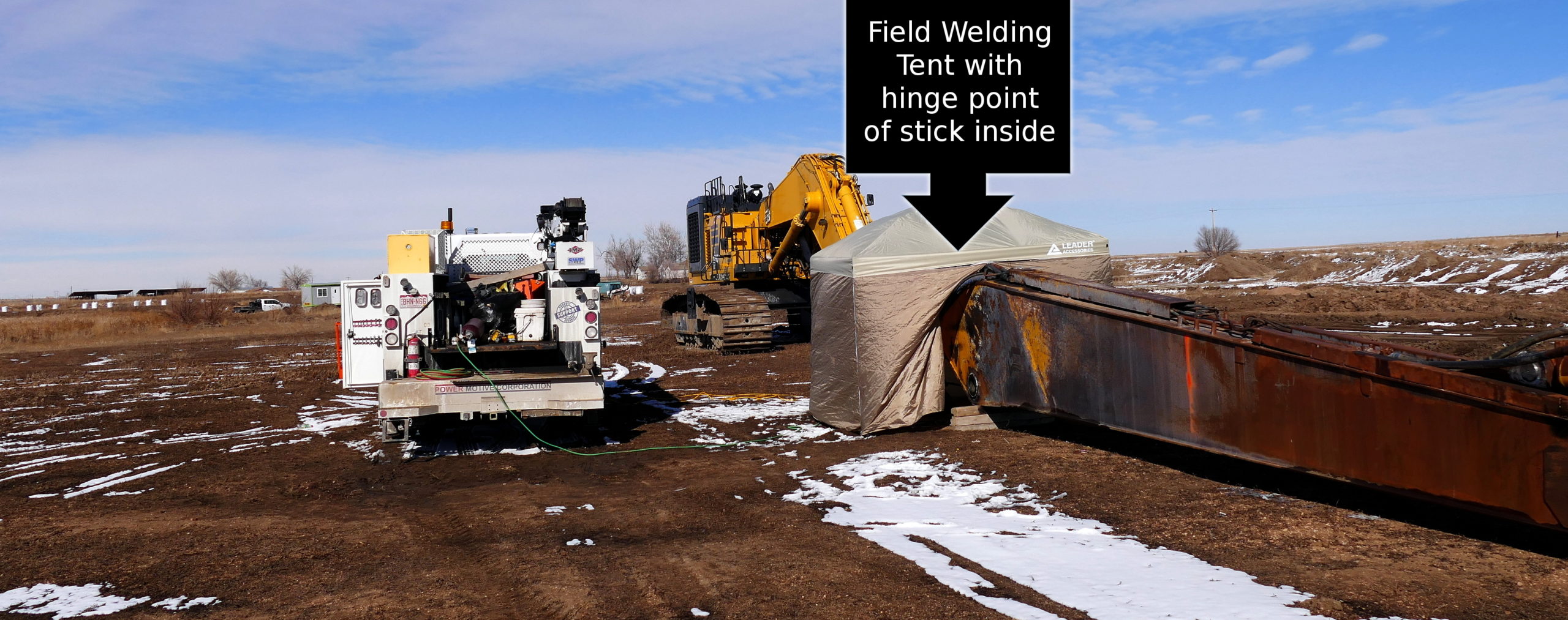

Field welding tent with hinge point of stick inside.

Project Description

This project involved the repair/reinforcement of a piece of heavy equipment. These sorts of projects are expensive – we were brought a cardboard template and asked to produce parts in 48 hours. It required us to generate the CAD on an unusual piece of geometry, allow for weld prep, and to iterate on that design using physical prototypes. But, as you will see, the equipment in use is also quite costly to sit idle. So the customer had budget and incentive to help us expedite this challenging project to completion.