What if I don’t have CAD files for my design?

We are capable of providing fairly advanced services for creating CAD for use with waterjet cutting. This will make your project more expensive than if you provided the CAD. There are some situations where this will result in a successful project, and some that are less likely to make economic sense.

Artistic Projects:

–Purely artistic, no critical mechanical fit required: We have had good success in taking an artist’s pen and paper drawings and creating CAD from those. This does require an approval cycle for you to approve the actual design-to-be-cut. The biggest challenge is coming to agreement that our implementation of your design is close enough. There is usually not budget sufficient to cover more than one design change process, so the closer your original drawings are to what you will accept, the greater the likelihood of your satisfaction.

–Artistic but some mechanical fit required: This is probably the most challenging situation. Usually this is a very low-quantity project with little budget to allow for re-design/re-cutting if the initial fit is not acceptable. The lack of a precise technical specification (in the form of customer-provided CAD) makes for a tenuous situation. We will only accept a narrow range of projects in this more risky category, and the pricing will reflect our best-effort to accommodate this risk.

Industrial Projects:

–Small quantity, difficult to replace parts, not available from original source: This is usually a project that is crucial enough to your operation that there is budget to handle a re-design/re-cut if needed.

–Larger quantities: Quantities make the budget large enough to handle a re-cut, and frequently larger quantities will produce later order re-using the CAD we created, making those re-orders very cost-effective since we do not bill you for the CAD design work on ensuing orders.

–Exceedingly simple geometries: Sometimes you just need a rectangle, or a rectangle with one hole in the center, or some other very simple, easily describable geometry. We can usually create CAD data for these quite quickly and inexpensively, and they are straightforward for you to review before we cut them.

Quantities and Overall Size of Project:

All of the above considerations are very dependent upon the overall size of the project’s budget and the quantities being cut. Larger projects increase the likelihood of more design resources being applied to a job, and therefore the likelihood of a very successful outcome…smaller projects have inherently more risk and will be more expensive on a part-by-part basis to reflect that risk.

Can I supply my own material?

Yes. Whether you supply your own material or we source it, your parts are cut with the same equipment, processes, and standards.

To get an idea of your costs, view our estimator tool. If this is your first time requesting a quote from Colorado WaterJet, take a moment to read our design file preferences.

Please note:

- We have a $200 minimum order cost.

- If your file was created in a CAD Program, please send as a .DXF, .DWG, .STP, or .STEP file type.

- If your file was created in a vector graphics program, please send files to us as .AI, .SCV or .EPS format.

- For all other sketches and file types, please review our design file preferences.

- File uploads must be less than 25 MB.

- If your order has many parts, fill out our parts spreadsheet and include it in your request.

- We cannot use images for which the customer does not own the trademark or usage rights.

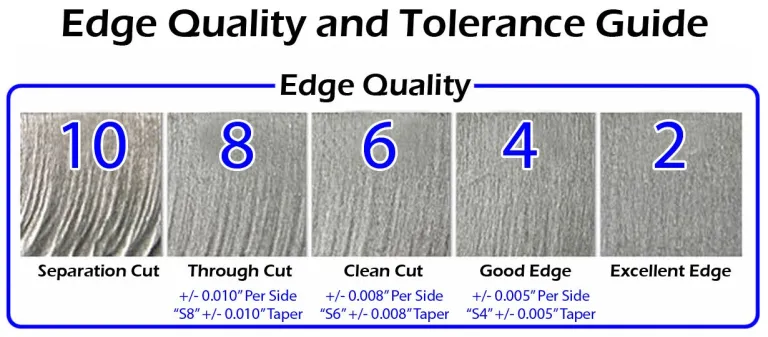

- Edge quality details are helpful but not required: