Resources

Frequently Asked Questions

What is Water Jetting?

The abrasive waterjet process works by cutting metal or other materials using a focused stream of highly pressurized water mixed with abrasive aggregate. The cutting head is Computer Numerically Controlled (CNC), achieving a precision of ±0.003″ per side.

High-pressure water hits the material at three times the speed of sound, carrying fine garnet abrasive in the stream with it. This combination of water and garnet cleanly erodes the material without transferring any heat into the process.

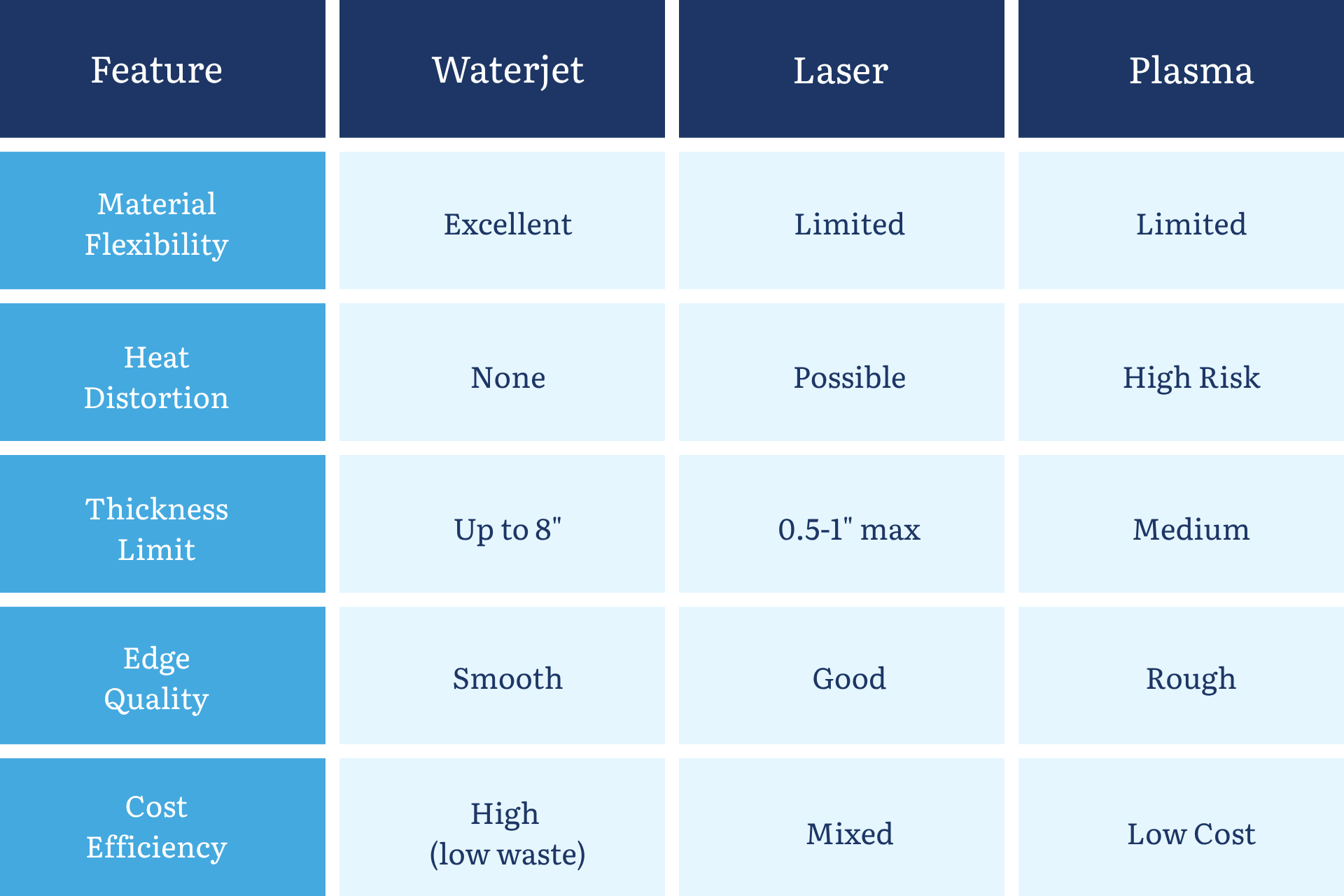

What materials are best suited for waterjet cutting?

Waterjet performs best on metals, plastics, and composites where heat-free cutting, clean edges, or precision are essential. We can also cut soft materials like foam, rubber, and tile when clean profiles and minimal compression are required.

What materials can you cut?

We cut most metals, plastics, and composites, including titanium, carbon fiber, UHMW, and laminates. We also handle rubber, foam, and stone-based materials.

Waterjet cutting is generally not used for tempered glass

[See full list on our Materials page.]

What thickness can you cut?

Any material thickness within our cutting envelope: Min material thickness: .001” to max material thickness: hard materials up to 8″, softer materials up to 12”.

Can I supply my own material?

Yes. Whether you supply your own material or we source it, your parts are cut with the same equipment, processes, and standards.

Can you cut my materials using the same process and benchmarks?

Yes. Whether you supply your own material or we source it, your parts are cut with the same equipment, processes, and standards.

Can you cut prototypes and production parts?

Yes. We can cut single prototypes or scale up to full production quantities with the same process.

Do you provide certifications or traceability for materials?

Yes. We can include material certifications, traceability documentation, and inspection reports with your parts when needed. Our internal Quality Management System ensures every project is tracked and documented to meet your requirements.

What is your typical turnaround time?

Our standard turnaround time is 2 weeks for most jobs. If you’re working on a tight deadline, we also offer 1-day, 3-day, and 5-day expedited options depending on scope.

Do you offer expedited services?

Yes. Our standard turnaround is 2 weeks, but we offer 1-day, 3-day, and 5-day expedited options for projects that need to move fast.

Can a waterjet handle layered materials?

Yes. We frequently cut multi-sheet layers, and composite assemblies with repeatable accuracy and minimal setup time.

What industries do you serve?

We work with manufacturers across aerospace, defense, medical, energy, industrial equipment, and other regulated sectors. We’re ITAR Registered, maintain a robust internal Quality Management System (QMS) and pass audits from ISO-driven customers.

What if I don’t have CAD files for my design?

We are capable of providing fairly advanced services for creating CAD for use with waterjet cutting. This will make your project more expensive than if you provided the CAD. There are some situations where this will result in a successful project, and some that are less likely to make economic sense.

Artistic Projects:

–Purely artistic, no critical mechanical fit required: We have had good success in taking an artist’s pen and paper drawings and creating CAD from those. This does require an approval cycle for you to approve the actual design-to-be-cut. The biggest challenge is coming to agreement that our implementation of your design is close enough. There is usually not budget sufficient to cover more than one design change process, so the closer your original drawings are to what you will accept, the greater the likelihood of your satisfaction.

–Artistic but some mechanical fit required: This is probably the most challenging situation. Usually this is a very low-quantity project with little budget to allow for re-design/re-cutting if the initial fit is not acceptable. The lack of a precise technical specification (in the form of customer-provided CAD) makes for a tenuous situation. We will only accept a narrow range of projects in this more risky category, and the pricing will reflect our best-effort to accommodate this risk.

Industrial Projects:

–Small quantity, difficult to replace parts, not available from original source: This is usually a project that is crucial enough to your operation that there is budget to handle a re-design/re-cut if needed.

–Larger quantities: Quantities make the budget large enough to handle a re-cut, and frequently larger quantities will produce later order re-using the CAD we created, making those re-orders very cost-effective since we do not bill you for the CAD design work on ensuing orders.

–Exceedingly simple geometries: Sometimes you just need a rectangle, or a rectangle with one hole in the center, or some other very simple, easily describable geometry. We can usually create CAD data for these quite quickly and inexpensively, and they are straightforward for you to review before we cut them.

Quantities and Overall Size of Project:

All of the above considerations are very dependent upon the overall size of the project’s budget and the quantities being cut. Larger projects increase the likelihood of more design resources being applied to a job, and therefore the likelihood of a very successful outcome…smaller projects have inherently more risk and will be more expensive on a part-by-part basis to reflect that risk.

Can you cut material I supply?

The short answer is “yes.” The longer answer takes into account cost of materials vs cost of setup times.

Cost of Materials vs Cost of Setup times

If you have something pre-fabricated (such as an enclosure like these), it makes perfect sense for us to cut assemblies you provide.

If you need several pieces all out of the same material, it can be much more cost-effective for us to cut out of a single sheet of material we supply rather than out of multiple pieces you supply. The setup charges for each new piece of material placed on the table can exceed the cost of the material. This presumes, of course, your material isn’t something particularly exotic/expensive like carbon fiber, fiberglass, laminates, or pre-formed metal pieces.

Ready to Get Started?

Request a quote, and we will respond quickly to discuss your project requirements.